Materials Innovation for a Better World

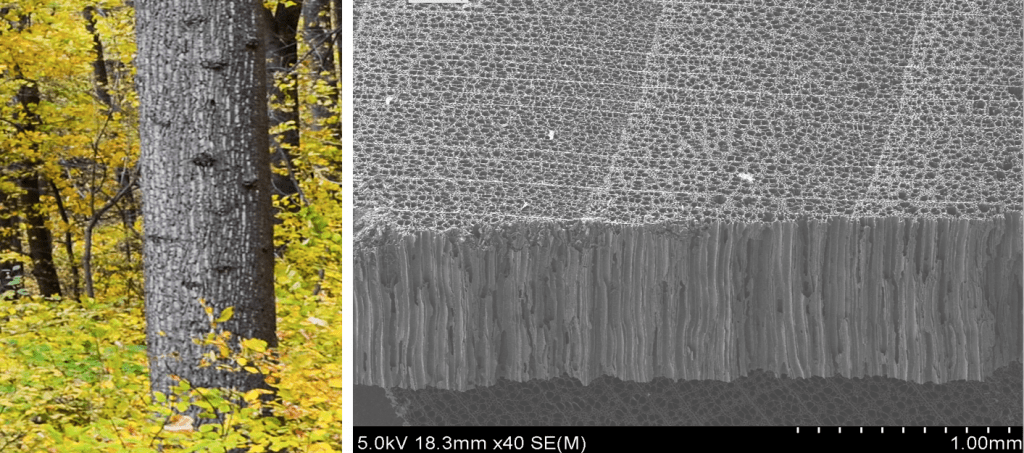

WOOD NANOTECHNOLOGY

Wood is one of the most abundant biomaterials on Earth, with over 3 trillion mature trees in the world. The unique material structure of wood, with pronounced anisotropy, endows it with an array of remarkable properties and functions, inspiring fertile opportunities for unconventional applications in multifunctional material design. The Center for Materials Innovation (CMI) aims to devise novel approaches to manipulate water, ions, photons, phonons, and mechanical properties by redesigning and reconstructing wood materials via structural engineering, chemical/thermal modification, hybridization with other materials, and the artificial creation of wood structures. Such strategies will enable a diverse range of emerging unconventional applications in high-performance structural materials, energy storage and conversion, water treatment, thermal and light management, ionic nanofluidics, green electronics, biological materials, and more.

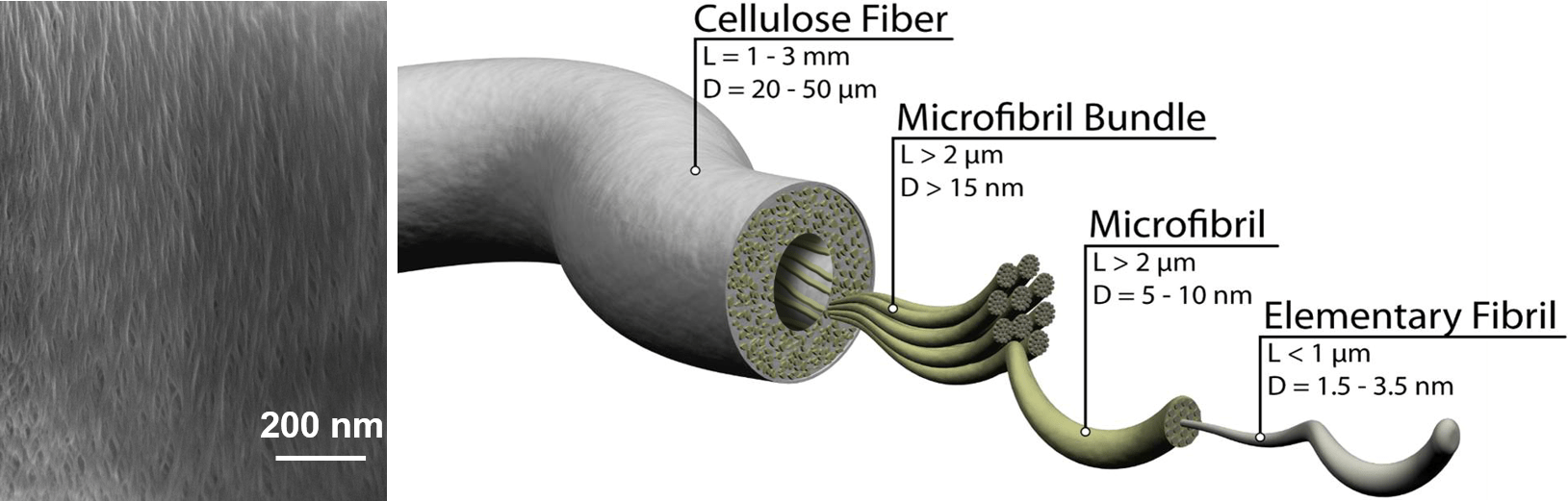

NANOCELLULOSE

As the most abundant polymer on Earth, cellulose features a hierarchical structure that extends down to the nanoscale. The nanoscale building blocks of cellulose allow exciting interactions with photons, phonons, and ions toward the development of unique optical, thermal, fluidic, and mechanical properties that far surpass the traditional limit of cellulose. As a new family of nanomaterials, nanocellulose offers a unique and complementary solution for addressing a broad range of technical challenges that go beyond just sustainability and biodegradability, though these are also important advantages of the material. At CMI, we will focus our studies on nanocellulose for more advanced functional structures in broad applications.

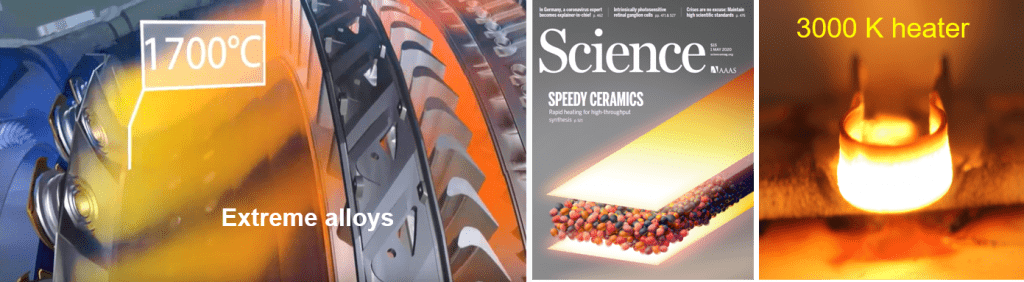

EXTREME MATERIALS

Extreme materials, like ceramics, metals/alloys, and glasses, can be successfully applied in high-temperature and high-pressure environments where other materials would normally fail. However, such compounds require prolonged, high-temperature processing, which limits our ability to screen and discover new materials. To overcome this limitation, we have invented an ultrafast high-temperature sintering (UHS) process that can rapidly synthesize and sinter solid materials in just ~10 seconds, greatly accelerating the development of high-performance extreme materials. At CMI, we are interested in inventing and manufacturing the next generation of extreme materials for a broad range of applications.

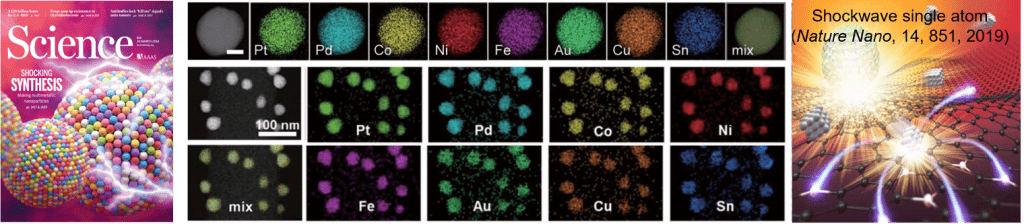

CATALYST

Catalysis is at the core of the chemical industry and is the enabling technology for state-of-the-art clean energy conversion applications. However, current catalysts are mostly limited to 1–3 elements due to the increasing challenging (e.g., immiscibility) of alloying multiple elements at the nanoscale. We have invented a series of facile yet highly effective high-temperature shock techniques that enable the synthesis of uniformly distributed, single-phase multielemental (≥ 3) nanoparticles, including metallic alloys, oxides, carbides, and intermetallics. The successful synthesis of these multielement (high-entropy) nanoparticles greatly broadens the material choice for catalysts to a virtually unlimited compositional space. At CMI, we are interested in inventing and applying low cost yet durable catalysts for wide-ranging technologies.

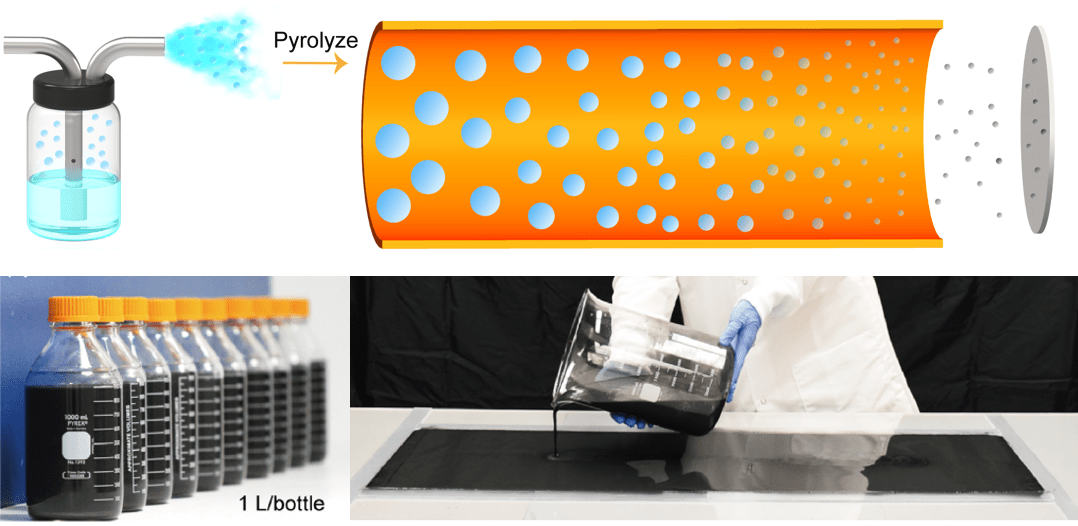

MATERIALS MANUFACTURING

At CMI, we are interested in scaling up invented materials from the lab to industry scale to realize broad societal impact. Our main focuses include (1) solution-based roll-to-roll printing; (2) high-temperature enabled rapid processing; and (3) traditional manufacturing, such as molding and extrusion techniques, with a goal of manufacturing new materials for future technologies.

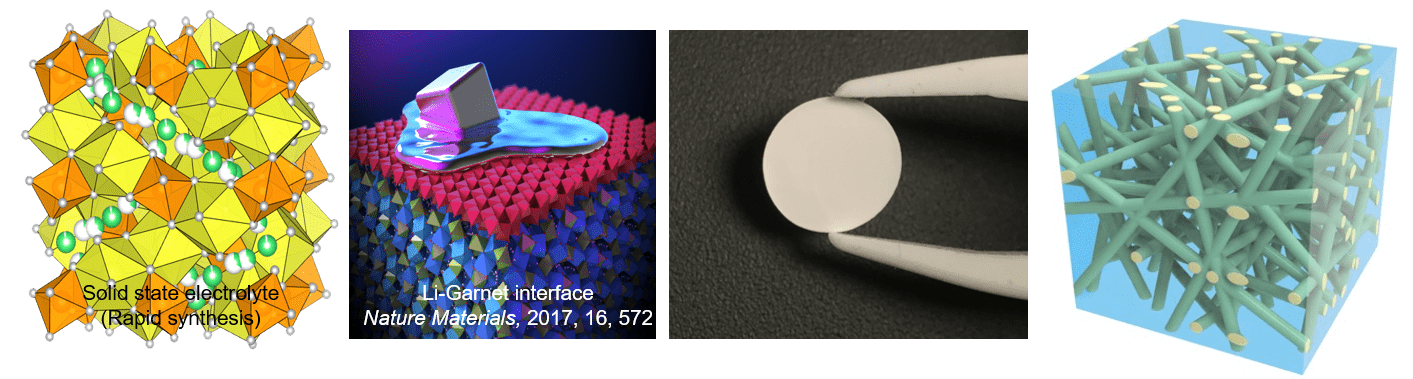

BATTERY MATERIALS

At CMI, we are investigating a range of battery materials to address challenges in energy storage. Our focuses include: (1) solid-state batteries (new electrolyte, new battery structures); (2) nanomaterials to enable fast yet safe battery charging; and (3) novel battery materials that can outperform the current state-of-the-art. Toward these aims, CMI has invented an ultrafast high-temperature sintering (UHS) method that can fabricate ion conductive membranes in just ~10 seconds. The center is now expanding this technique to a range of new battery materials (e.g., electrodes, electrolytes, and coatings).

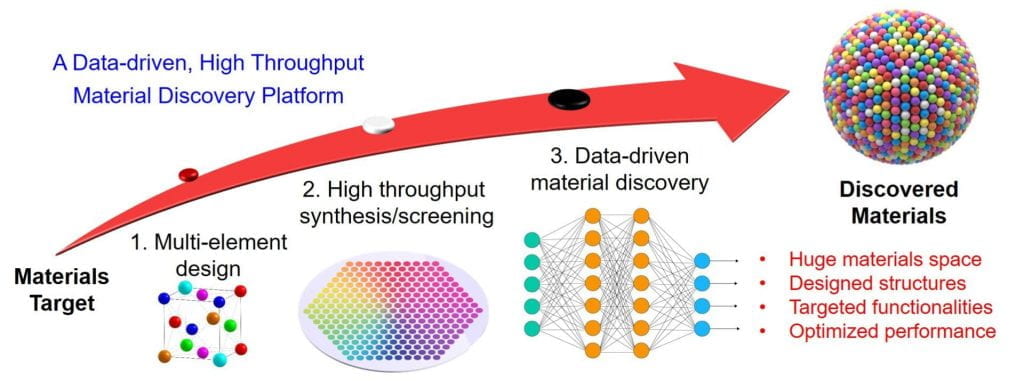

MACHINE LEARNING/AI

From wood nanotechnologies to multielemental alloys, the rapid discovery and manufacturing of future materials will heavily rely on machine learning and artificial intelligence (AI). At CMI, we are collaborating with experts to: (1) integrate advanced computational tools, such as first principles computation, machine learning/AI, and data mining for materials discovery and design; (2) combinatorial, high-throughput materials synthesis for rapid screening and data generation; and (3) the use of AI to rapidly optimize materials manufacturing processes.