02/17/2023

Hu Lab Welcomes St. Louis Catholic School First lego League Team

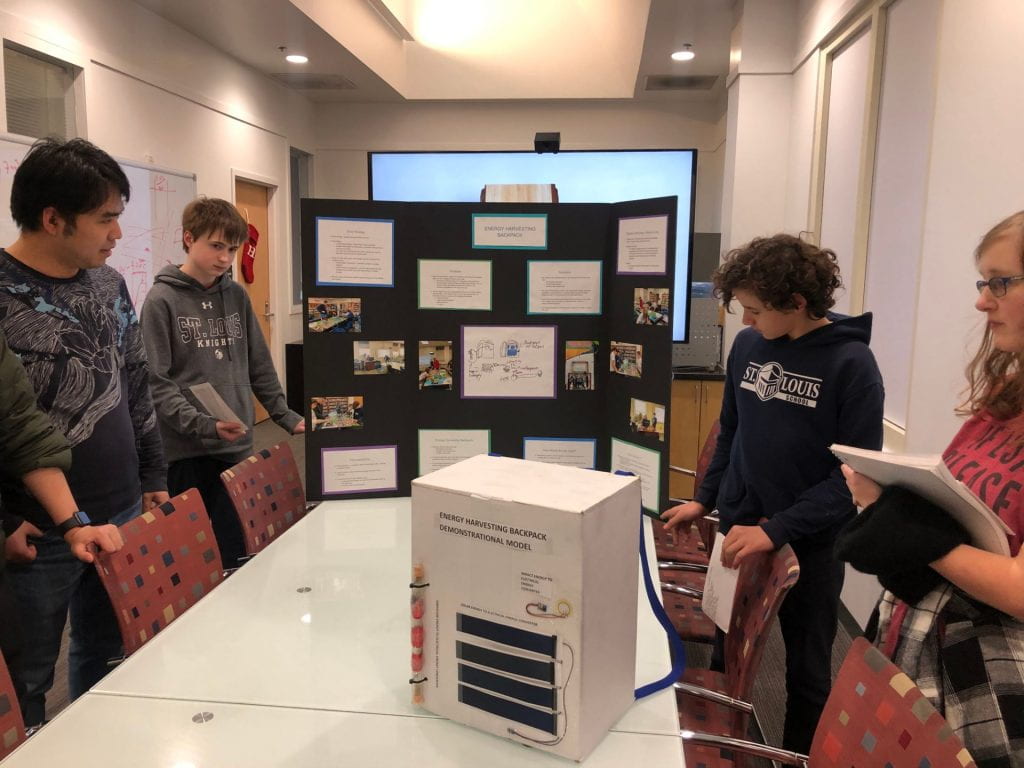

Hu lab members welcomed the First Lego League Team from St. Louis Catholic School in Clarksville, Maryland on Friday! The First Lego League Team Members have a practice presentation on their energy harvesting backpack project, which did well at the First Lego League Regional Qualifier Competition. The team will be competing in the State Tournament later this month. The students learned about some of the ongoing research from the Hu Lab, including Superwood and sustainable thermal insulation.

08/01/2022

Maryland Scientists Publish on the Cover of Nature Nanotechnology

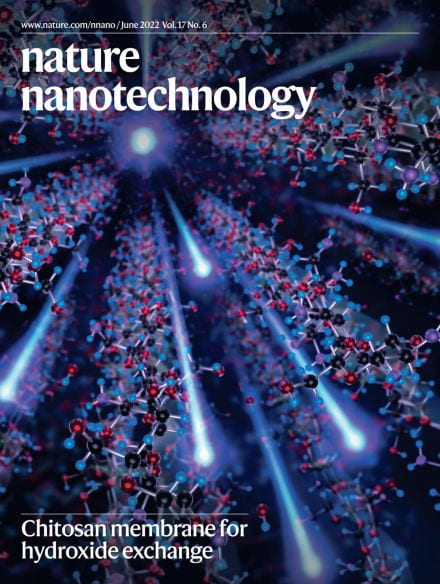

Ion exchange members are widely used to selectively transport ions in various electrochemical devices. Maryland scientists have discovered that a membrane, with 1 nm nanochannels made by crosslinking chitosan molecules with copper ions, shows promising performance for hydroxide exchange applications. The study, led by Liangbing Hu, Herbert Rabin Distinguished Professor of MSE and Director of the Center for Materials Innovation at UMD, was published on the June cover of Nature Nanotechnology. Meiling Wu, an assistant research scientist in Hu’s group, served as the first author on the study. Click this link to read more.

04/30/2022

Hu Lab Presents Interactive Exhibit at Maryland Day

The Hu group created an interactive family-friendly exhibit to display ongoing research at Maryland Day! The booth taught children and families about superwood, wood-based insulation foam, x-ray diffraction, and chitin polymers. Check out some of the pictures below to see the setup!

04/19/2022

Maryland Team Hunts for $100 Million Climate Victory Prize

Prof. Ning Zeng, a professor of atmospheric and oceanic science at the University of Maryland (UMD), is leading a team in a multiyear global competition for fighting against climate change and carbon emissions. The team, titled Wood Vault, is competing in Elon Musk’s XPrize Carbon Removal Challenge by working on a highly efficient carbon-removal “device” that cleans the air and soaks up climate-changing gas via trees. Click here to read more.

04/06/2022

Maryland Scientists Enhance Electrochemical Reactions

Prof. Liangbing Hu, a professor of materials science and engineering (MSE) at the University of Maryland (UMD), and Yuyan Shao, a materials scientist at the Pacific Northwest National Laboratory, have co-led a project to increase the durability of platinum group metal-free (PGM-free) electrocatalysts. The team used metal oxide nanoparticle additives to protect PGM-free electrocatalysts from the attack of the most powerful oxidizing radical, hydroxyl radicals (·OH), as demonstrated in a recent paper published March 25th in Nature Energy. Click here to read more.

02/15/2022

Prof. Liangbing Hu Granted $5.6 Million in DOE ARPA-E Funding

Prof. Liangbing Hu, Director of Center of Materials Innovation at the University of Maryland, was recently awarded a total of $5.6 million in funding from the U.S. Department of Energy Advanced Research Project Agency-Energy (ARPA-E). The funding is part of the ARPA-E OPEN 2021 program, which prioritizes funding technologies that support novel approaches to clean energy challenges. The selected projects will advance energy storage and catalysis technology respectively. The UMD project, “Fast-Charging, Solid-State, Roll-to-Roll Processed Li Metal Batteries Enabled by Intercalated Ions in Cellulose Molecular Channels,” was endowed with $2.6 million. Hu’s team aims to fabricate fast-charging batteries in which the electrolyte comprises a cellulose fiber-based ion conductor. HighT-Tech’s project – “Scalable Manufacturing of High-Entropy Alloy Catalysts for Ammonia Oxidation” – was granted $3.0 million to create scalable manufacturing processes of high-entropy alloy (HEA) catalysts for ammonia oxidation with enhanced catalytic activity, selectivity and stability. Click here to read more.

10/22/2021

Maryland Scientists Develop Bamboo-based Alternative for Synthetic Fibers

The research team led by Liangbing Hu, Materials Science and Engineering Professor and Director of the Center for Materials Innovation, has developed a renewable and biodegradable wood-derived fiber suitable for potential use in structural composites. The study, titled “Sustainable high-strength microfibers extracted from bamboo,” was published on December 16, 2021, in Nature Sustainability. Click here to read more.

10/22/2021

Maryland Engineers Develop Sustainable Sharp Knives from Wood

The research team led by Teng Li, Professor of Mechanical Engineering, has developed a more sustainable way to make sharp knives using hardened wood. The study, titled, “Hardened wood as a renewable alternative to steel and plastic,” was published on October 20, 2021, in Matter. Click here to read more.

10/21/2021

Maryland Scientists Fabricate Moldable Wood using a “Water Shock” Process

Our research team led by Liangbing Hu, Materials Science and Engineering Professor and Director of the Center for Materials Innovation, has developed a technique for creating strong and moldable wood materials via a rapid “water-shock” process. The study, titled, “Lightweight, Strong, Moldable Wood via Cell Wall Engineering as a Sustainable Structural Material,” was published on October 20, 2021, on the cover of Science. Click here to read more.

10/20/2021

Maryland Scientists Expand Wood Fibers for High-Performance Solid-State Paper Batteries

We recently expanded the molecular channels of cellulose nano-fibrils (i.e., tiny, thread-like tubes, mechanically derived from trees) via copper ions to achieve a more efficient ion conductor. The study, led by Prof. Liangbing Hu, titled, “Copper-coordinated cellulose ion conductors for solid-state batteries,” was published on October 20, 2021, in Nature. Click here to read more.

05/10/2021

Prof. Liangbing Hu Named 2021/2022 Distinguished Scholar-Teacher

Liangbing Hu, Herbert Rabin Distinguished Professor in the University of Maryland (UMD) Department of Materials Science and Engineering (MSE) and Director of the Center for Materials Innovation, has been named a 2021-2022 Distinguished Scholar-Teacher. The UMD Distinguished Scholar-Teacher Program, established in 1978, honors a small number of faculty members every year who have demonstrated exceptional success in both scholarship and teaching. Awardees are expected to make a public presentation on a topic within their expertise, and receive an honorarium of $5,000 to support their professional activities. Click here to read more.

04/01/2021

Maryland Scientists Synthesize Metallic Glass Nanoparticles via High-Temperature Thermal Shock

Synthesizing metallic glass nanostructures is a challenging task due to large differences among multiple glass-forming elements as well as a lack of effective methods to induce glass formation at nanoscale, which typically requires a rapid quenching rate > 10^3 K/s. To make this process more efficient, a research team in the University of Maryland (UMD) Department of Materials Science and Engineering (MSE) led by Prof. Liangbing Hu – Center for Materials Innovation (CMI) Director – for the first time synthesized a multinary metallic nanostructure dispersed on thin graphene substrates. This is achieved by using a unique far-from-equilibrium synthesis technique called ‘high-temperature thermal shock,’ invented at UMD. Upon rapidly heating to a high temperature, these elements are mixed uniformly; rapid quenching (on the order of 10^5 K/s) immediately following could lead to rapid solidification, which is fast enough to avoid crystallization, thus forming the unique metallic glass nanostructures. This research was conducted through multi-disciplinary collaboration with research teams at UMD, UCLA, and Berkeley National Laboratory. This study was published in Nature. Click here to read more.

03/27/2021

Prof. Liangbing Hu joins the Advisory Panel of Nature Sustainability

Prof. Liangbing Hu, Director of Center of Materials Innovation and Herbert Rabin Distinguished Professor at the University of Maryland College Park (UMD) Department of Materials Science and Engineering (MSE), joins the Advisory Panel of Nature Sustainability. Nature Sustainability is a journal publishing the best research about sustainability from the natural and social sciences, as well as from the fields of engineering and policy. Click here to read more.

03/25/2021

Maryland Scientists Published Recyclable Lignocellulosic Bioplastic to Replace Plastics

More than 380 million tons of plastic are produced each year. To solve the server environmental problems brought by the usage of plastics, a University of Maryland research team led by Prof. Liangbing Hu – Center for Materials Innovation Director – recently developed a simple yet cost-effective in situ lignin regeneration approach to synthesize a strong, large-scale, hydrostable, biodegradable and recyclable lignocellulosic bioplastic, produced 100% from an abundant and inexpensive wood powder, which is generally discarded as waste. The study, entitled, “A strong, biodegradable and recyclable lignocellulosic bioplastic,” was published in Nature Sustainability. Click here to read more.

03/23/2021

Prof. Liangbing Hu Selected to be the Class of 2021 MRS Fellows

Prof. Liangbing Hu, Director of Center of Materials Innovation and Herbert Rabin Distinguished Professor at the University of Maryland College Park (UMD) Department of Materials Science and Engineering (MSE), is selected to the class of 2021 MRS Fellows of the Materials Research Society (MRS) for his pioneering studies in the areas of wood nanotechnologies, ultra-high temperature manufacturing and for uncovering new materials and methods for energy storage and conversion, printed electronics and wearables. The title of MRS Fellow honors those MRS members who have outstanding contributions to the field, including research, leadership, and service that have advanced the mission of the materials community worldwide. The highly selective distinction is limited up to 0.2% of the current MRS regular membership each year and to those with continuous engagement with MRS. Dr. Hu is the first scholar from UMD to win this prestigious recognition. J.C. Zhao, MSE Professor and Chair, was named an MRS Fellow for the 2019 class while serving The Ohio State University; he joined UMD in July, 2019. Congratulations to Dr. Hu! Click here to read more.

02/03/2020

Maryland Scientists Published a Perspective of Using Nanocellulose as a Sustainable Technological Material towards Addressing Global Challenges

Nanocellulose lines the cell walls of plants, trees, algae, and bacteria consisting of glucose rings that link together like a chain and give it a rigged structure. In a perspective published in Nature, a University of Maryland (UMD) research team led by Prof. Liangbing Hu – Center for Materials Innovation (CMI) Director – offers a perspective of using nanocellulose as a sustainable technological material towards addressing global challenges. Tian Li and Chaoji Chen, both MSE and CMI Scientists, served as the first authors on the paper. Click here to read more.

01/11/2020

Maryland Scientists Designed Denary Oxide Nanoparticles as Highly Stable Catalysts

The mixing of multiple elements brings new functionality to materials, which exhibit excellent durability in long-term operations as a result of the ‘entropy stabilization effect.’ The composition of existing oxide nanoparticles, however, has been constrained to a maximum of five metal cations and is limited by conventional methods. To this end, our research team at UMD developed a novel strategy to design and synthesize a library of MEO nanoparticles (up to 10 cations) with tunable composition, size, and structure. The study, led by Dr. Liangbing Hu, Herbert Rabin Distinguished Professor and director of the Center for Materials Innovation at UMD, was published on the January 2021 cover of Nature Catalysis. Tangyuan Li, a postdoctoral associate in Professor Hu’s group, served as the lead author of the research paper. This research was conducted through multi-disciplinary collaboration with research teams at the University of Illinois at Chicago, John Hopkin’s University, the University of Pittsburgh, the University of California at San Diego, and Oak Ridge National Laboratory. Click here to read more.

11/18/2020

Maryland Researchers Develop a New Method of Printing and Sintering Solid-State Batteries

We recently developed a new method of printing and sintering a variety of SSE thin films. This work, entitled, “Printable, high-performance solid-state electrolyte films,” was published on November 18, 2020, in Science Advances. The team named this method ‘printing and radiative heating’ (PRH), which features a solution-based printable technique followed by rapid sintering. Click here to read more.

11/18/2020

A new ARPA-E Project Enabled by UHS Sintering Method.

The University of Maryland is leading a new ARPA-E project, titled New Environmental-Thermal Barrier Coatings for Ultrahigh Temperature Alloy. We will leverage a newly invented, ultrafast high-temperature sintering (UHS) method to perform fast exploration of new environmental-thermal barrier coatings (ETBCs) for 1300°C (2372 °F)-capable refractory alloys for harsh turbine environments. UHS enables the ultrafast synthesis of high-melting oxide coatings, including multilayers, in less than a minute, enabling rapid evaluation of novel coating compositions. By using UHS with fast-fail tests and modeling and analytics tools, the team will be able to explore hundreds of compositions and coating architectures to design and optimize 1700°C (3092 °F)-capable ETBCs with different layer sequences, thicknesses, porosity levels, and novel compositions.

11/17/2020

Inventwood is Recognized Among Maryland’s Future 20 Start-Up Companies by Governor Hogan

In celebration of National Entrepreneur’s Day, Governor Larry Hogan today announced Maryland’s Future 20, a list of innovative startups from various industries that have the potential to be the state’s next major business success story. The Maryland Future 20 is part of Innovation Uncovered, an ongoing initiative by the Maryland Department of Commerce to highlight the state’s talented innovators, entrepreneurs, and growing small businesses. More than 125 nominations were received from the business community and general public, and the final list was selected based on a variety of factors, including innovation, future growth potential, the company’s Maryland story, and “wow” factor. Inventwood, a start-up founded by the Director of CMI, Liangbing Hu has been recognized on this prestigious list.

11/16/2020

Former Postdoctoral Researchers from CMI Receive MRS 2020 Postdoctoral Awards

Tian Li and Chengwei Wang, both formerly postdoctoral researchers in the University of Maryland (UMD) Department of Materials Science and Engineering (MSE) have received 2020 postdoctoral awards from the Materials Research Society (MRS). Click here to read more.

10/02/2020

Our Study on High Entropy Alloy Catalysts Has Won a 2020 R&D 100 Award

Our study on high entropy alloy catalysts (Science 2018) has won a prestigious 2020 R&D 100 Award in the Mechanical/Materials category. Click here to read more.

10/01/2020

Our Work on Transparent Wood is Featured on the USDA Website

Our recent work collaborating with Forest Products Laboratory (FPL) researcher Junyong Zhu on transparent wood materials is now published on Advanced Functional Materials and featured on the USDA website. Click here to read more.

09/13/2020

Maryland Researchers Create Elastic Wood

Our recent work on fabricating a highly elastic, ionically conductive, anisotropic elastic wood directly from natural wood is now published on ACS Nano and reported in C&EN magazine. Click here to read more.

08/24/2020

Our Research on Aesthetic Transparent Wood is Featured in the Editors’ Highlights of Nature Communications.

Our paper published in Nature Communications, titled “Scalable Aesthetic Transparent Wood for Energy Efficient Buildings,” is now featured in the Editors’ Highlights. Transparent wood composites are promising engineered materials for green energy-efficient buildings. We demonstrate novel aesthetic wood with integrated functions of optical transparency, UV-blocking, thermal insulation, and mechanical strength for sustainable applications. Click here to read more.

08/08/2020

Dr. Liangbing Hu, Director of CMI, Is Leading a New ARPA-E Project.

Dr. Liangbing Hu is leading a new ARPA-E project, titled Rapid Encapsulation of Pipelines Avoiding Intensive Replacement (REPAIR). The University of Maryland (UMD) has proposed a multifaceted and integrated approach to develop a smart alloy coating for use in pipe-in-pipe configurations. With UMD’s patented high-temperature sintering process, a novel smart alloy coating can be rapidly sintered with a high-temperature Joule heating bar directly from the alloy powders in approximately 10 seconds. The coating can be scaled to meet commercial market demands due to its high sintering density, mechanical strength, and self-healing properties. UMD’s technology is targeted to be capable of generating new steel pipe to replace older infrastructure at a lower cost for gas service and with improved mechanical strength and corrosion resistance for a 50-year lifetime.

07/27/2020

Our study on a High-Capacity, Long-Life Li-CO2 Battery Based on a Flexible Wood Cathode Architecture is Reported by BBC Future

The Li–CO2 battery is considered a promising platform for CO2 capture, with the ability to utilize the captured CO2 for energy storage. However, the Li–CO2 battery still suffers various inadequacies, including slow kinetics of CO2 reduction, high charge/discharge hysteresis, an ultra-stable discharge product, and slow transport of CO2 gas and electrolyte. To overcome these challenges, Liangbing Hu, Director of the Center for Materials Innovation at UMD, recently constructed a battery using readily available, porous, holey of wood as the electrodes. This study has been published in Energy & Environmental Science and reported by BBC Future.

06/12/2020

Ph.D. Candidate from CMI Receives NSF Graduate Research Fellowship

Dylan Kirsch—currently a Ph.D. candidate in the University of Maryland (UMD) Department of Materials Science and Engineering (MSE) and Center for Materials Innovation (CMI)—received a 2020 National Science Foundation (NSF) Graduate Research Fellowship (GRF). Dylan is co-advised by Prof. Takeuchi and Prof. Hu. The NSF-GRF offers three years of funding, renewed annually, in support of masters and doctoral research in STEM fields. The fellowship will support Kirsch’s current research, which focuses on materials physics, as part of a DOE-funded collaboration between the Stanford Linear Accelerator Laboratory (SLAC), UMD, the National Institute of Standards and Technology (NIST), as well as several other universities. Congratulations to Dylan! Click here to read more.

05/29/2020

Highlights of Our Research Group are Reported on the Spring Newsletter of MSE

In the newly published Techtracks Newsletter of the Department of Materials Science and Engineering, several highlights of our group are reported. Our new ultra-fast high-temperature synthesis was featured on the May 1 cover of Science (Dr. Hu’s second Science cover). This invention will have a substantial impact on future materials synthesis. Dr. Hu was also recently bestowed with the title of Herbert Rabin Distinguished Professor of Engineering and is the Founding Director of the new Center for Materials Innovation, which will bolster collaborative materials development to address global challenges. In addition, students and postdocs from our center have won numerous awards in the past few months, including the highly competitive 2020 MRS Postdoctoral Award (Tian Li) and one of Nature‘s five Emerging Stars in the field of materials science (Emily Hitz). In addition, Tian Li has accepted a full-time position as an assistant professor at Purdue University, beginning August 17, 2020. Congratulations on the new position and awards! Click here to read more.

05/27/2020

Our Review Paper on Garnet-Type Solid-State Electrolytes is Published on the Cover of Chemical Reviews

Garnet-type electrolyte has been considered one of the most promising and important solid-state electrolytes for batteries with potential benefits in energy density, electrochemical stability, high-temperature stability, and safety. Led by Liangbing Hu, Herbert Rabin Distinguished Professor in the Department of Materials Science and Engineering and Director of the Center for Materials Innovation at UMD, this review paper surveyed recent developments of garnet-type Li7La3Zr2O12 (LLZO) electrolytes with discussions of experimental studies and theoretical results, along with LLZO electrolyte synthesis strategies and modifications, the stability of garnet solid electrolytes/electrodes, emerging nanostructure designs, degradation mechanisms and mitigation strategies, and battery architectures and integrations. This paper was published on the April 9 cover of Chemical Reviews. Chengwei Wang, an assistant research scientist in Hu’s group, and Kun Fu, currently an Assistant Professor at Delaware University and a former postdoc from Hu’s group, served as the co-first authors on the review paper.

05/15/2020

Our Study on Superfast Method for Ceramic Manufacturing is Reported in the American Ceramic Society

Our new superfast sintering method, published on the May 1 cover of Science, is reported in the American Ceramic Society. Click this link to read more.

04/30/2020

Our New Study on a Superfast Method for Ceramic Manufacturing is Published on the Cover of Science

Ceramics are widely used in batteries, electronics, and extreme environments—but conventional ceramic sintering (part of the firing process used in the manufacture of ceramic objects) often requires hours of processing time. To overcome this challenge, our research team at UMD has invented an ultrafast high-temperature sintering method that both meets the needs of modern ceramics and fosters the discovery of new material innovations. The study, led by Liangbing Hu, Herbert Rabin Distinguished Professor of MSE and Director of the Center for Materials Innovation at UMD, was published on the May 1 cover of Science. Chengwei Wang, an assistant research scientist in Hu’s group, served as the first author on the study. Click this link to read more.

04/27/2020

Maryland Researchers Create an Exceptionally Strong, Lightweight Material out of Microwaved Bamboo

Our recent work on the rapid manufacturing of strong, tough, and light materials made from bamboo was published in ACS Nano on April 10. Click this link to read more.

04/24/2020

Maryland Engineers Open the Door to a Big New Library of Tiny Nanoparticles

The development of bimetallic nanoparticles (i.e., tiny particles composed of two different metals that exhibit several new and improved properties) represents a novel area of research with a wide range of potential applications. Now, a research team in the University of Maryland (UMD)’s Department of Materials Science and Engineering (MSE) has developed a new method for mixing metals generally known to be immiscible, or unmixable, at the nanoscale to create a new range of bimetallic materials. Such a library will be useful for studying the role of these bimetallic particles in various reaction scenarios such as the transformation of carbon dioxide to fuel and chemicals. The study, led by Liangbing Hu, was published in Science Advances on April 24. Click this link to read more.

04/02/2020

Maryland Researchers Report Micro-Reactor that Produces Quality Nanoparticles

Large-scale manufacturing of nanoparticles is vital for many applications but maintaining uniform quality is difficult. We have recently developed a “droplet-to-particle” technique with the potential to produce uniform alloy/oxide nanoparticles. Spraying an aerosol of the nanoparticle ingredients into a high-temperature furnace is an efficient means of producing large amounts of nanomaterials continuously. But the furnaces used in aerosol spray pyrolysis typically only reach temperatures of ~1500 K, limiting the types of nanoparticle that can be produced as well as the quality. To overcome this challenge, Wang and coworkers at the Universities of Maryland, Illinois at Chicago, and California Riverside replaced the tube furnace with a micro-channel reactor, formed from charred balsa wood, which possesses natural channels on the scale of 200 µm. This study, led by Liangbing Hu, was published in Materials Today. Click this link to read more.

03/28/2020

University of Maryland Announces Launch of the Center for Materials Innovation

The A. James Clark School of Engineering announced the launch of the Center for Materials Innovation (CMI), a multidisciplinary research center to bring together faculty members from across the UMD campus and partner institutions to invent, manufacture and use innovative materials to address pressing societal issues, from sustainability and the energy-water nexus to energy efficiency and beyond. Click this link to learn more.